We're rolling over to an improved version of Blockplate's starting with the "Blockplate 24". The new version is called "blockplate 24".

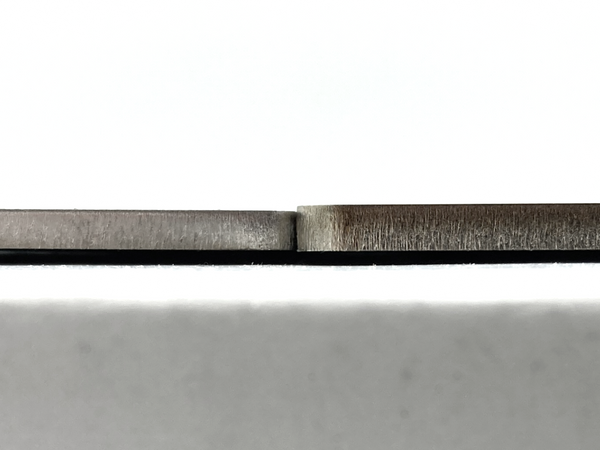

See for yourself! (New on the bottom, old on the top)

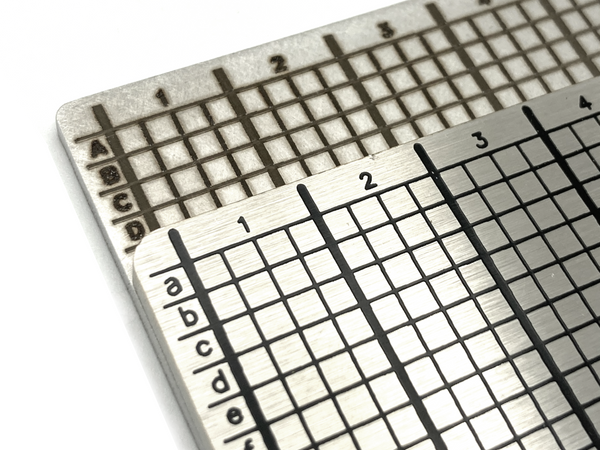

lowercase

We've transitioned from using UPPERCASE letters to lowercase letters. This change was to align with the BIP39 wordlist where lowercase is utilized.

Why does it matter? Technically, it doesn't. The BIP39 wordlist only uses lowercase letters. In addition, when it comes to generating a seed phrase, the words themselves aren't even used.

But, it matters behind the scenes in the programming of wallets. Specifically how developers allow users to enter seed phrases and how they implement the BIP39 specification with regards to key mapping (i.e. getting to your keys).

In a nutshell, when you enter your seed phrase into a wallet, it takes that seed phrase and puts into a series of functions (a set of instructions with an input and output) to get to your keys.

Case sensitivity is important when the wallet puts your seed phrase into those functions because in programming, the data for the letter "A" is different than "a".

Wallet developers have a multitude of options on how to handle uppercase letters and most do appropriately.

But, we wanted to avoid invalid seed phrases and prevent confusion in the event a wallet did not consider users entering uppercase letters.

There's a bit more explanation on this aspect so we wrote an article on it: Is a Seed Phrase Case Sensitive?

Chemical Engraving

We have switched from laser engraving to chemical engraving.

With laser engraving, the material is vaporized via heat resulting in a melted, crater-like impression. This creates a "messier" engraving due to uncontrollable variables during the process.

The chemical engraving process uses chemicals (instead of heat) to remove material from the plate of a specified design. This provides better control of the process and improved quality of the marking. Layers of material are "dissolved" to create an clean, precise impression. In addition, there are no heat stresses in the material better preserving its mechanical properties.

Color Filled

Since we are not using heat, the color of the actual plate is unchanged (only the physical metal is removed via chemical engraving).

Chemical engraving does not create that "burned" black/brown color that is typically seen with heat based engraving processes (some customers believed this was "rust" and we wanted to avoid that misconception).

Instead, you're left with a clean engraving with no change in material color (other than the difference in finish of the engraving) and only depth.

We color filled these engravings with black to give a better contrasting appearance between the engraving and the plate. This color is purely for aesthetic purposes and has no impact on the properties of the engraving or plate.

The color fill is very durable but will not last forever (like any sort of ink or paint). The engraving on the other hand will continue to last since layers of material were physically removed during the chemical engraving process.

Thicker

We are using thicker metal.

The material is the same with the same finish (304 stainless steel, brushed) but now 11 gauge stainless steel (instead of 12 gauge)

Remember with "gauge" measurements, the smaller the number, the thicker the metal.

11 gauge stainless steel (right) is ~0.02" thicker than 12 gauge stainless steel (left).